China's current Five Year Plan seeks to improve conditions for workers, with electronics one of the priority sectors. James Rose looks at the challenges that must be overcome

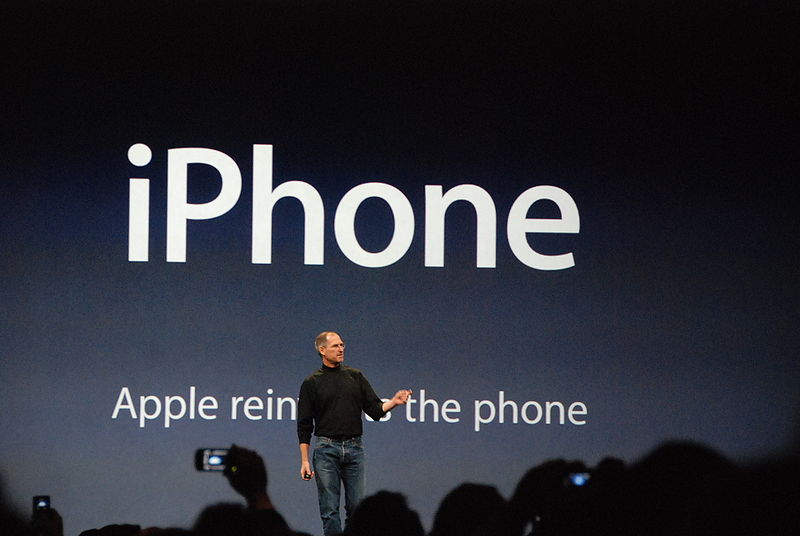

When the first Apple iPhone landed in the second half of 2007, it went on to sell 6 million units in its first year, across four countries. The turnaround time to market for this first model was six months. By 2012, the turnaround was two weeks and Apple was moving 230 million iPhones to more than 100 countries.

This phenomenal growth, mirrored in various degrees across the whole industry, is arguably the fastest and biggest supply chain development for any sector, ever. As supply chains have been put on steroids, the impact on workers in the electronics sector has been pointed. In the opinion of Hong Kong-based academic Jack Linchuan Qiu, it’s been “a bloody decade of labour abuse”.

The electronics supply chain is long. Not only is it bloated with workers on the production line, but it reaches backwards into the mining of raw materials, so-called 3TG minerals, and forwards to include e-waste disposal.

The seemingly unending litany of labour abuses by suppliers has tarred the entire electronics supply chain out of China

Also, the market is rapidly changing. Recent years have seen shifting product trends as the global market for PCs and laptops drops, and demand for ever-newer versions of smartphones and their components takes up a higher proportion in sales.

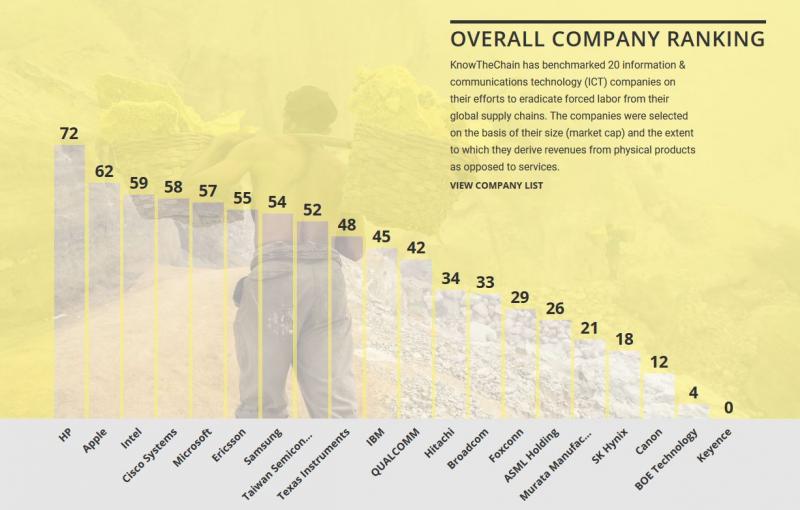

China is the undoubted capital of the electronics sector supply chain, so much so that the suppliers that source Chinese labour, like Foxconn, Pegatron or Quanta, are almost as well known as the brands they serve. The seemingly unending litany of labour abuses run out by such suppliers has tarred the entire electronics supply chain out of China. According to a landmark 2016 survey by KnowTheChain, the electronics sector remains at risk in terms of human rights standards.

The report says that although 18 of the 20 companies researched show they have committed to addressing human rights abuses in their supply chains, “far fewer of these companies also have strong processes in place to implement these commitments”.

The relationship of Apple with the Taiwanese-owned Hon Hai Precision Industry – Foxconn – in particular, and its massive Chinese factory base, is central to the growth of the mobile phone sector and characterizes the sector in some eyes.

While Apple has improved its human rights performance, Foxconn still lags. In its study, KnowTheChain scores the company zero in important worker-outreach categories such as “worker voice”, “worker eEmpowerment” and “stakeholder empowerment”.

As such, it’s a relationship that is peppered with corporate ethics landmines that others in the sector need to map.

With its 1.3 million employees, almost all of them in Chinese electronics factories, Foxconn has become a byword in supply chain exploitation.

Students in China are often compulsory “interns” - threatened with a fail mark in their courses if they refuse

Foxconn is not alone. Most recently, investigations aired by the Hong Kong-based Students and Scholars Against Corporate Misbehaviour (SACOM) alleged that students in China are often coerced to work in electronics factories run by Taiwan-based manufacturer Quanta Computer, which produces for brands such as Apple, Dell, HP, Sony and Acer. These compulsory “interns” are threatened with a fail mark in their courses if they refuse. It’s a practice Foxconn has been engaged in for some time, according to earlier SACOM reports.

There have been signs of improvement. Apple, after copping waves of criticism on its supply chain now ranks second on KnowTheChain’s benchmark for good performances in areas such as transparency, disclosure, commitment, workforce recruitment and remedy programmes.

However, the sector still lands regularly in hot water. This may be reflective of a functionality gap: although recognition and awareness of the problem is relatively high, positive action is often not present.

KnowTheChain’s overall assessment is that companies in this industry consistently fall short in worker-centric policy and programming. Apple, for instance, scores zeroes, like Foxconn, in the worker voice and worker empowerment categories.

According to KnowTheChain, the vast majority of large UK-registered companies in the ICT sector fell well short on anti-slavery disclosures, even given three years of the UK Modern Slavery Act.

The Verité report caused us to dig deep into forced labour

Standardization has increased and consolidated as the industry in China has grown, and as sustainability problems have become better understood.

This appears to be continuing as the newly re-badged Responsible Business Alliance (RBA), formerly the Electronic Industry Citizenship Coalition, revamps its agenda.

The RBA’s name change, in late 2017, is more than just a rehash and rebrand. The new moniker represents an ongoing attempt by the industry to adopt a broader and deeper coverage of its services and membership.

Chinese workers are beginning to wake up to their power. (Credit: Artwell/Shutterstock)

In 2014, the group was shocked at revelations by Verité, an NGO that addresses human rights in supply chains, that one-third of migrant labourers employed in the electronics sector in Malaysia were bonded labour. This prompted the development of new codes of conduct for members and a new audit regime.

“The Verité report caused us to dig deep into forced labour,” the body’s CEO, Rob Lederer told Ethical Corporation at the time. “We probably have the toughest code of conduct out there now.”

According to a statement, the RBA is now extending that rigour, incorporating “companies with products in which electronics are essential to the primary focus on the product”.

Companies working with Chinese supply chains need a broad and flexible approach, and more qualitative thinking

Previous changes opened the way for those in the toy, aviation, auto and wearable tech industries, among others, to sign up to the organization, thus providing a more appropriate coverage of the sector.

Perhaps the most important value-add in the latest iteration is better synchronization of the RBA’s sub-sector bodies, such as the newly re-named Responsible Minerals Initiative and the Responsible Labour Initiative.

Such developments are in synch with the Chinese government’s priorities as its economy enters a new phase of maturity after three decades of high growth. According to the International Labour Organisation, improving the quality of employment and living standards for workers are central planks of Beijing’s 13th Five Year Plan for economic and social development from 2016 to 2020.

The ILO is working with the government to deliver the new agenda through its China Decent Work Country Programme 2016-2020. This includes through expanding the Sustaining Competitive and Responsible enterprises (SCORE) programme, a practical training and counselling programme that aims to improve productivity and working conditions in small and medium enterprises. In China it is targeted at factories in the automotive, textiles and electronics sectors.

SACOM members protest against Apple and its ties with labour supplier Foxconn. (Credit: SACOM)

Dr Guo Peiyuan, managing-director of SynTao, a Beijing-based CSR consultancy, says companies working with Chinese supply chains need a broad and flexible approach, and more qualitative thinking.

He recommends a four-fold approach: do a baseline analysis, disclose information in CSR reports, engage in dialogue with suppliers rather than rely on third-party audits, and “use language and terms that can be understood by local people and government”.

At the core of Dr Guo’s advice is communication. While standards and protocols certainly have a role to play, ensuring an open and expansive dialogue with all stakeholders is perhaps the real key to building living, breathing human rights cultures on the ground.

It’s worth noting, Chinese workers are awakening to their power

This squares with the aims of various civil advocates for human rights in Chinese supply chains, including the International Labour Organization’s (ILO) China Decent Work Country Programme 2016-2020.

Caution is needed also to ensure buyer companies don’t over-audit, and get tangled in duplication and cross-referencing, a pitfall it seems the RBA is seeking to address.

Such an approach can divert companies away from the very sources of long-term solutions: workers and other stakeholders. Standards and audits can be a trap without a contextual view.

It’s worth noting – Chinese workers are awakening to their power. In 2010, for instance, wide-ranging and unprecedented strike action shook the country and ruffled the feathers of many suppliers. This outbreak abated, but strikes continue. The US-based China Labor Bulletin (CLB) tracked 465 strikes across the country between January and June 2017, remarkable in a country where the only recognized union is government-aligned, and where striking carries significant personal risk.

Most of the strikes were for “pay arrears”. Such actions, says the CLB, define China’s “new economic normal”.

KnowTheChain’s report highlighted the lack of worker-centric programs in the sector. The “worker voice” category ranked lowest of the seven themes covered in the survey, with an average score of just 16/100.

As the China employment market matures, a new era presents a moment to take stock. As the sector shape shifts again, there is some good reason to ensure vital company supply chains are secure and sustainable via a functional human rights culture.

James Rose has been a corporate social responsibility commentator, consultant and researcher for more than 20 years. He is former Asia-Pacific editor of Ethical Corporation.

This article is part of the in-depth briefing China’s New Dawn. See also:

Green bond market helps China’s green revolution overcome headwinds

China looks offshore for its new renewable frontier

Chinese companies slow to join RE100

Women and children first: how brands are innovating to help China’s female workers

IKEA and Audi pulled up for sexist marketing

Global goals: Huawei’s strategy to connect the world – and take on Apple

The brands going beyond auditing to give China’s apparel workers a voice

How QuizRR is taking human rights training to the factory floor

China’s toy industry in push to improve conditions for migrant workers

How Mattel’s quick move rescued Barbie